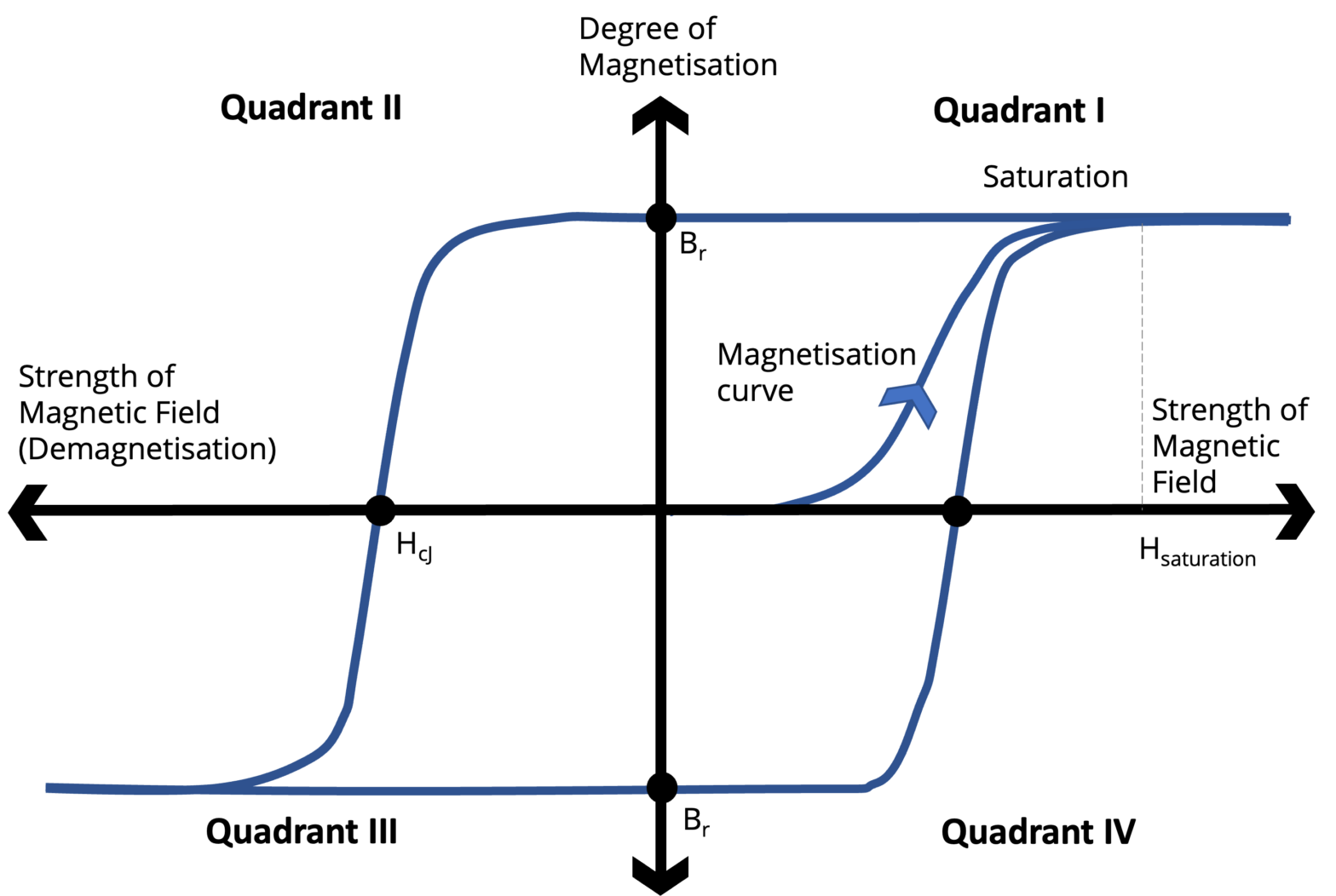

The first commercially available Pulsed Field Magnetometer (PFM) from Hirst was announced in 1998 (with the first machine shipped in 1999) but research work had been started 10 years earlier as it was clear modern high coercivity magnets could not always be measured on the traditional permeameters due to pole piece saturation and faster tests were needed by magnet makers and magnet users. The latest generation of PFMs can measure permanent magnet samples up to 70mm over a wide range of temperatures from -40 to over 230 degrees celsius with up to 20 tests per hour at full precision with class leading repeatability on key parameters such as HcJ of better than ±0.2%, with full sample reload. Small sample kits are also available to test samples down to 1x1x1mm. As you will see from this history overview PFMs can deliver very fast measurements with test times as short as 5 seconds as well as ultra high precision measurements making it the measurement of choice in quality control applications and research. With a built in magnetiser and demagnetiser the Hirst PFMs measure all four quadrants of the magnetic hysteresis graph in a single measurement. There is an IEC measurement standard IEC 60404 – 5 for the PFM technique and the story doesn’t end there as development is continuing on the use of PFMs for even more advanced magnet diagnostics.

Hirst recently wrote an overview article of its latest Generation 8 machines for UK Magsoc MagNews in Issue 2 2023 – this gives a good overview of this measurement technique.

Todays PFMs are mostly used in a quality control in magnet manufacture & in magnet end users as well as in magnet R&D but it all started 25 years ago in 1998 with the launch of the first commercial PFM from Hirst.

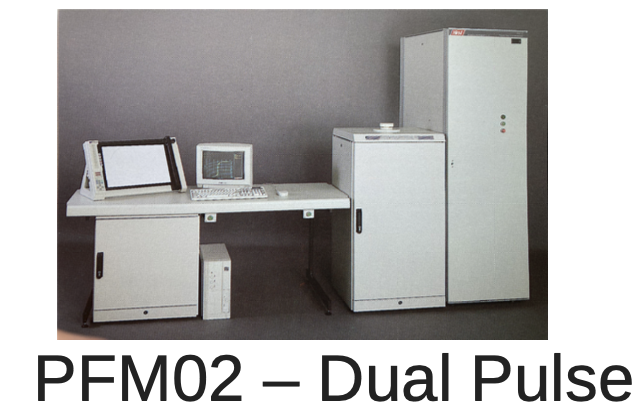

The first product the Dual Pulse PFM02 featured Hirst proprietary Eddy Current correction technique called F-2F and could measure any shaped magnet. The Dual Pulse PFM could generate 20 Tesla fields and measured samples around 5mm, it was a very laboratory focused machine and was sold in modest numbers to research institutes and Universities.

A copy of the original 1999 brochure can be downloaded here:-

Then in 2003 Hirst produced the PFM21 prototype as part of a collaborative EU project SMT-CT98-2212, showing just how fast measurements could be with PFMs with a fully automated sample loading and handling system that could test each magnet in less than 5 seconds !. Hirst never put this machine into production but the technology developed in this demonstrator showed just how powerful a tool the PFM could be in quality control offering the potential of 100% testing of magnets at about 1k samples per hour.

In 2006 and in collaboration with the National Institute of Metrology in Beijing, Hirst produced the PFM12.cn to meet the needs of magnet producers. It was the first to have a stabilised ambient temperature test with sample temperature control of ±0.1℃. This was important as temperature variations in tests resulted in changes in key parameters such as HcJ that were similar to those being measured. It was widely used in block testing of magnets by magnet makers in quality control. Some are still in service today but many have been replaced with later generations of machine with higher performance. The generation 2, PFM12.cn could measure samples up to 10mm with fields of up to 10.5T and in high precision mode, could measure up to 20 samples at any ambient temperature an hour (and up to 40 test an hour for samples close to lab temperature). A generation 3 version of the PFM12.cn was produced in 2008.

In 2009 the generation 4 machines were launched and the PFM15 was added to the range, this featured high temperature testing up to +220℃ with similar levels of temperature control to PFM12.cn but with a much more powerful magnetiser / demagnetiser to allow sample tests up to 50mm to meet the demands of National Labs and R&D groups.

Then in 2012 a high temperature capable version of the PFM12, the PFM14 was added. This was capable of high temperature testing up to 200℃ with a 10mm sample. These generation 5 machines were mostly sold to Chinese magnet manufacturers for quality control and magnet development.

In 2016 Hirst was the first to introduce a PFM capable of measuring samples as small as 1x1x1mm with a repeatability of HcJ of better than ±0.5%, with full sample reload. The PFM06 generated a 6T field and could measure samples from 5mm down to 1x1x1mm at a stabilised ambient with sample temperature control of ±0.1℃. The PFM06 was used in the development and quality control of grain boundary diffusion magnets (GBD) and selective GBD magnets.

In 2021 Hirst released its generation 7 versions of the PFM12 and PFM14 which featured higher levels of temperature sample stability and even greater repeatability with HcJ of better than ±0.2%.

The latest generation 8, PFMs launched in 2023 offer a wider range of sample sizes from 1x1x1mm up to 70mm with a maximum field of 10.5T (8356 kA/m / 105 kOe) even the most coercive materials and highest grades of NdFeB or SmCo can be measured, while traditional permeameters cannot measure these high coercivity materials due to pole piece saturation limitations. The 8th generation of PFMs from Hirst uniquely feature the eddy current correction (patented F-2F algorithm), Self-Demagnetisation Field (SDF) correction function (to allow accurate measurement of a wide range of samples from cylinders, cuboids and arbitrary sample shapes), and Hirst proprietary Self De-magnetisation Field Function SDFF™ (patented) which accurately generates an open to closed circuit mapping (O2C™). This allows Hirst PFMs to deliver closed loop equivalent measurements within 1% of a permeameter / hysteresis graph. The company won an Institute of Physics business award for the SDFF™ technology in 2020. HirstLab v2.0 software and Hirst proprietary SDFF™ technology has been implemented in collaboration with the National Institute of Metrology (NIM), Beijing, as part of a contract for the first 8th generation PFM placed by NIM.