Most applications require a custom made magnetising fixture to provide the best energy transfer between the magnetising fixture and the magnet. The design and construction of a custom magnetisation coil fixture involves detailed magnetic and thermal design – see magnetic design process for more details. To start the process just send us a drawing (.dwg / .dxf / .step) of your magnet assembly including specification of the magnet material and your production cycle time or volume aims and we can tailor a solution for you. Or if the design is at an earlier stage, we can work with you to optimise both production and design.

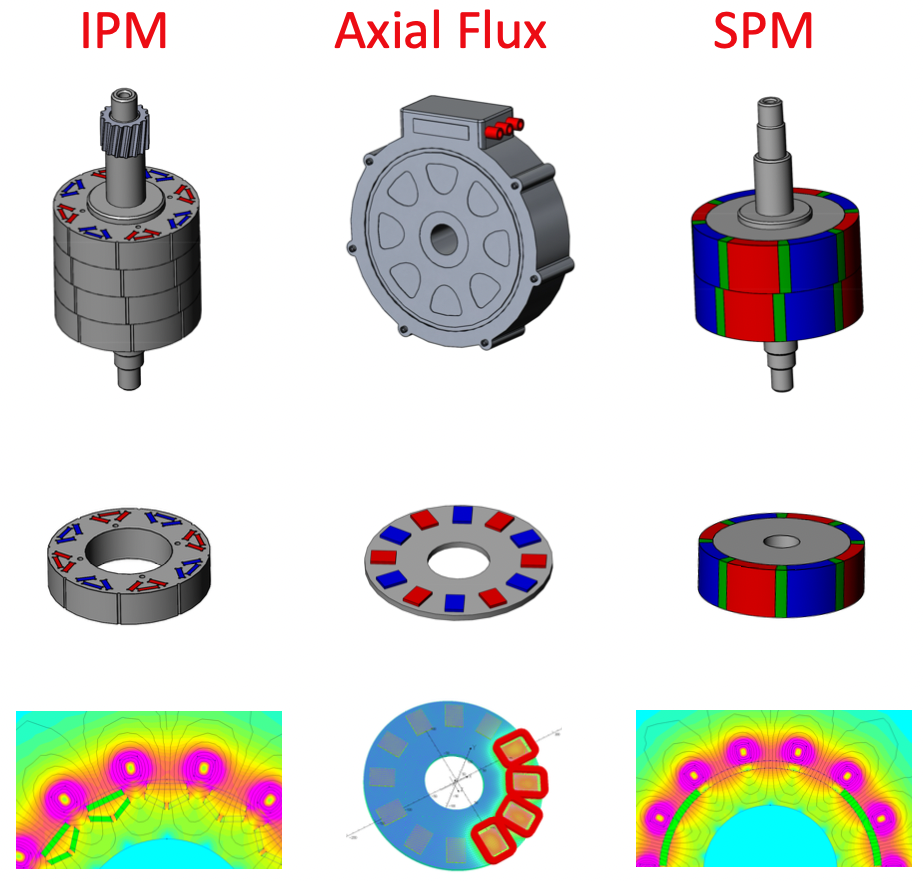

Electric Motors

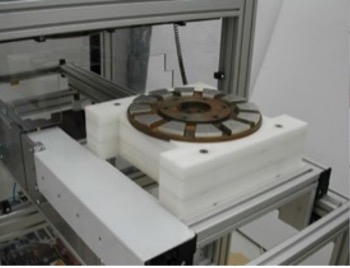

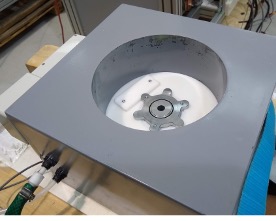

Hirst has designed custom fixtures magnetisation of rotors for all motor types including IPM (Interior Permanent Magnet) SPM (Surface Permanent Magnets) and Axial flux rotors.

Hirst has extensive experience of 2 to over 40 poles fixtures, Straight & Skew pole patterns, Halbach arrays and multiple magnet geometry layouts.

Hirst employ a range of construction techniques to deliver the best solution

- Iron and Steel based coils for large poles and high fields

- Non-magnetic former ‘air’ coils for small poles and axial rotors

- Resin and glass fibre moulding for mechanical strength and long term stability.

- Air cooled and water cooled fixtures

Most of our designs are developed under non-disclosure agreements so only a few can be show here.

Recycling magnets

Hirst has manufactured custom fixtures for making large ferrite magnets since 2005.

They are for 1-2 Tonne magnets used in over-band separators systems for recycling ferrous metals.

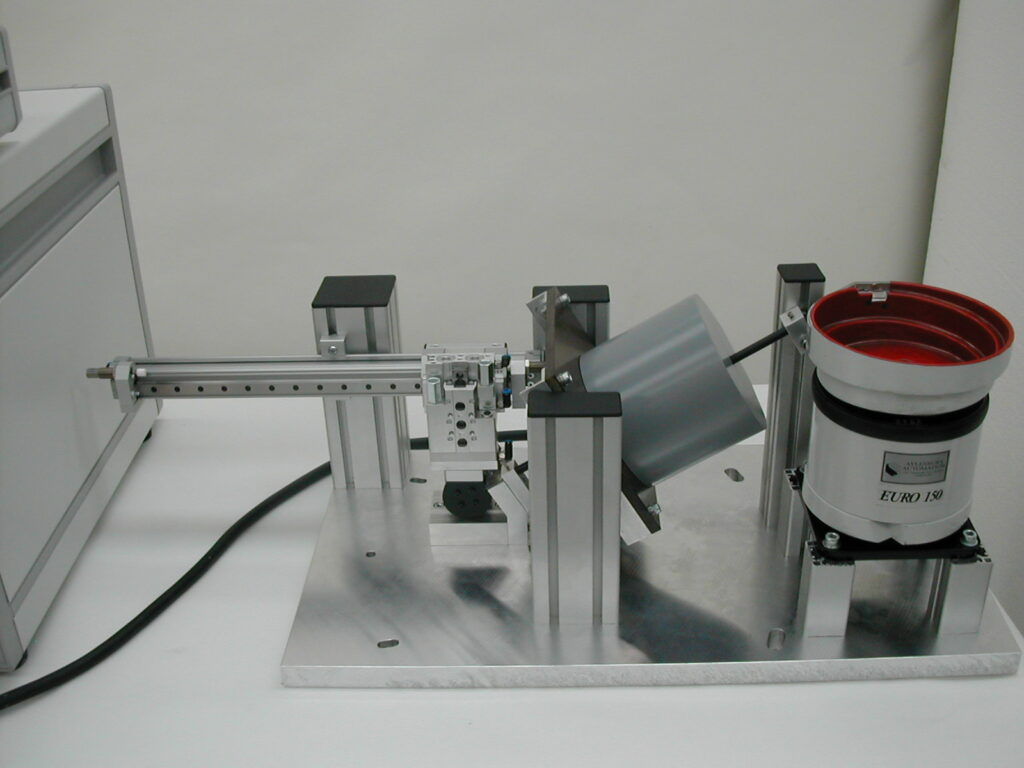

Loudspeakers

Hirst has manufactured many custom fixtures for production of loudspeakers of all sizes for general audio and premium performance audio applications. Hirst has been making fixtures for this application since the 1950s and Hirst equipment is used in several well know household names.

The smaller speaker fixtures are usually air cooled, although larger speaker fixtures are usually water cooled to increase cycle time.

Sensors

Hirst has manufactured custom fixtures for precision aerospace sensors magnetic calibration of sensors, critical aircraft sensors, backup compasses, cockpit oxygen sensors these fixtures are often used with the MCSD range precision magnetisers, calibrators, setters and demagnetisers.

Most sensor fixtures are air cooled.

Single Magnet Systems – consumer and industrial

Hirst has manufactured custom fixtures for consumer applications including high volume toys and industrial magnetisation applications for manufacture of reed relays, valves and actuators.