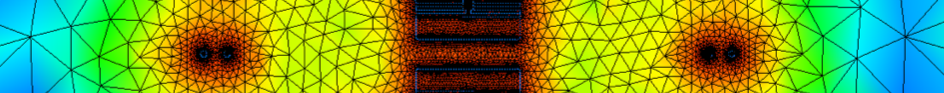

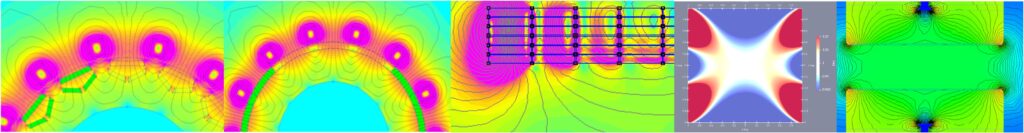

Hirst uses the latest in magnetics simulation and FEA (Finite Element Analysis) modelling software tools alongside SolidWorks CAD for all mechanical design work. As a team we are dedicated to offering our customer the right solution for the problem in hand. Hirst can work from concept drawings from the customers design team all the way through to designing a production system to manufacture a specific part at a given production throughput.

Everything, however starts with the magnetic design. The team of engineers, physicists, mechanical designers and magnetic experts at Hirst are always keen to take on novel magnetic and production challenges. Our engineers can manage all automation, production and integration challenges to deliver turn-key custom solutions.

Our custom made magnetic solutions have been employed all over the world in a wide array of applications, ranging from automotive industry to aerospace.

Examples of customer projects

- Aerospace – navigation compass – workstation magnetiser and custom 2 pole fixture

- Automotive – high power axial flux rotor – industrial magnetiser and water cooled 8 pole custom fixture – step and repeat, IPM, SPM motors of all sizes. Skew patterns, Halbach arrays and many multiple magnet geometry layouts.

- Medical equipment – demagnetiser – hypodermic needle batch de-magnetiser

- A Ferro fluid material separator

- Medical Research – a system for exposure of AC fields to biological samples

- Manufacture – Magnetic Forging equipment

- Material Research – A 20 Tesla pulse magnetisers

How to start

The design and construction of a custom magnetisation coil fixture involves detailed magnetic and thermal design. To start the process just send us a drawing (.dwg / .dxf / .step) of your magnet assembly including specification of the magnet material and your production cycle time or volume aims and we can tailor a solution for you. Or if the design is at an earlier stage we can work with you to optimise both production and design.