Employers need to take reasonable steps to prevent harm in the workplace and this includes considering any risks arising from exposure to electromagnetic fields (EMFs).

The HSE guidance Electromagnetic fields at work outlines an employer’s duties under the Control of Electromagnetic Fields at Work Regulations 2016. The guide explains what an Electromagnetic Field (EMF) is, what the law says and how to assess employees’ potential exposure to EMFs with reference to ‘action levels’ and ‘exposure limit values” experienced by those in the vicinity of this equipment. The standards referenced are in this guidance are part of the non-ionising radiation regulations in place in the UK and EU and which part of the Health and Safety working directives and legislation on the 1st July 2016.

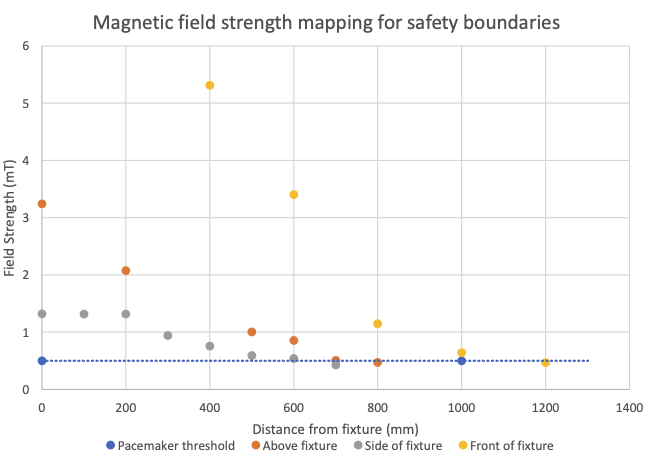

Magnetisers generate strong magnetic fields during the transfer of energy from the capacitor banks to the piece to be magnetised (mostly centred around the magnetising coil fixture) and it is recommended that a magnetic field safety check should be performed regularly to ensure compliance with UK and EU 2016 Health and Safety working directives on working with magnetic fields.

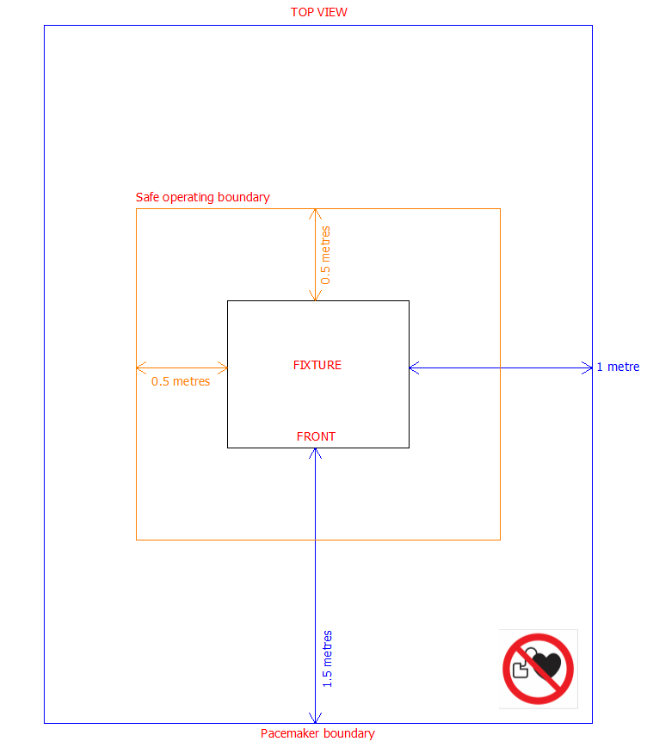

Hirst has expertise in designing equipment to comply with these guidelines. There are two main boundaries that need to be considered when operating a magnetiser and fixture the Standard Safe Operating Boundary for operators and the more stringent Pacemaker Safe Operating Boundary. Appropriate interlocks, signage and marking of boundaries are required for safe operation.

Hirst offers a Magnetic Field Mapping service which requires a 3 axis Gaussmeter and logging software. Hirst can advise on setting up a safe operation boundary and then should be verified annually. Contact us for more details or to book your Magnetic Field Survey and assessment visit.