Hirst Magnetic Instruments have been providing solutions for 60 years in magnetics and magnetic measurement. Hirst manufactures precision hand-held Gaussmeters, Fluxmeters, bench top & workstation industrial magnetisers & demagnetisers, industrial production-line magnetisers and Pulsed Field Magnetometers (PFMs) for developing / characterising magnetic materials.

Magnetic characterisation – PFMs

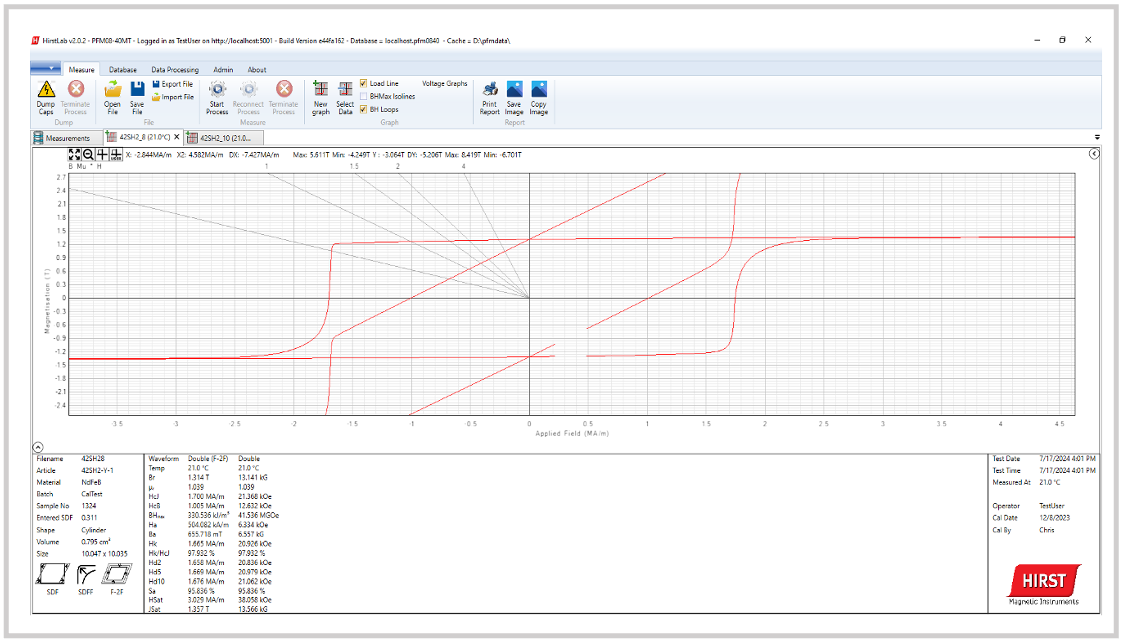

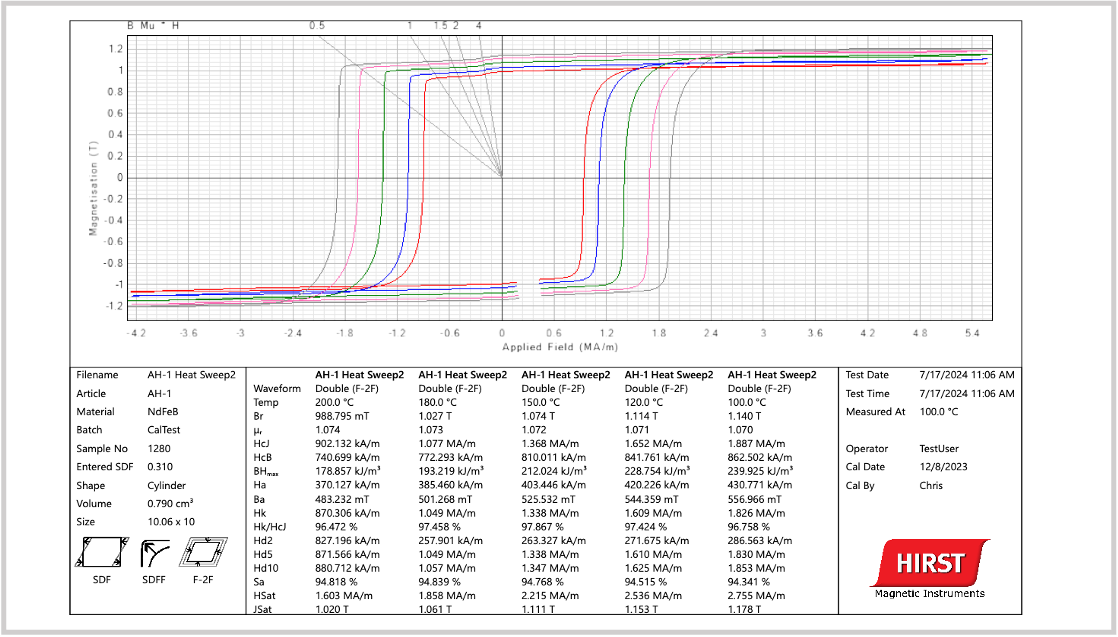

The PFM-08 range of magnet characterisation magnetometer can accurately measure the magnetic hysteresis loop and extract key values for all hard magnetic materials (Ferrite, NdFeB, SmCo and coated magnets). With a maximum field of 10.5T (8356 kA/m / 105 kOe) even the most coercive materials and highest grades of NdFeB magnets can be measured, while traditional permeameters cannot measure these high coercivity materials due to pole piece saturation limitations. The 8th generation of PFMs have world leading sample temperature control accuracy and test to test repeatability. They also uniquely feature the eddy current correction (patented F-2F algorithm), Self-Demagnetisation Field (SDF) correction function (to allow accurate measurement of a wide range of samples from cylinders, cuboids and arbitrary sample shapes), and Hirst proprietary Self De-magnetisation Field Function SDFF™ (patented) which accurately generates an open to closed circuit mapping (O2C™). The first generation of Hirst industrial PFM was launched in 1998 and the company won an Institute of Physics business award for the SDFF™ technology in 2020. HirstLab v2 software and Hirst proprietary SDFF™ technology has been implemented in collaboration with the National Institute of Metrology (NIM), Beijing, as part of a contract for the first generation 8 machine placed by NIM.

Find out more about Hirst PFMs

Measurement solutions

Hirst Magnetic Instruments has been active in providing solutions for 60 years in magnetics and magnetic measurement.

Hirst manufacture precision hand-held Gaussmeters, Fluxmeters and Helmholtz coils for measuring of magnets and magnet assemblies.

Find out more about Hirst’s range of Gaussmeters

Find out more about Hirst Fluxmeters

Find out more about Helmholtz coils for measuring

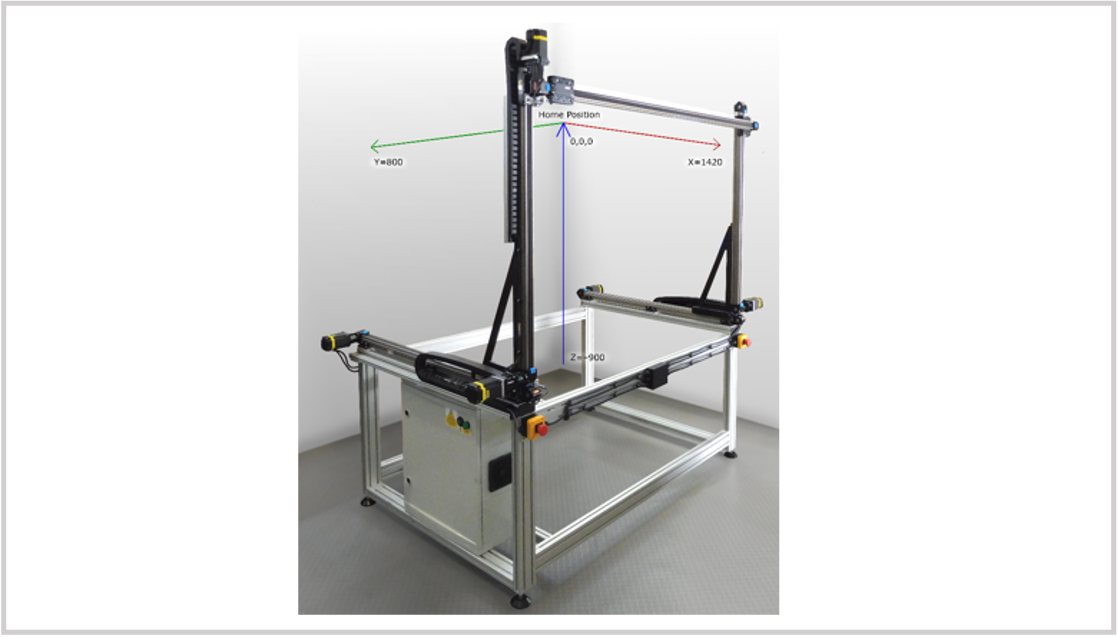

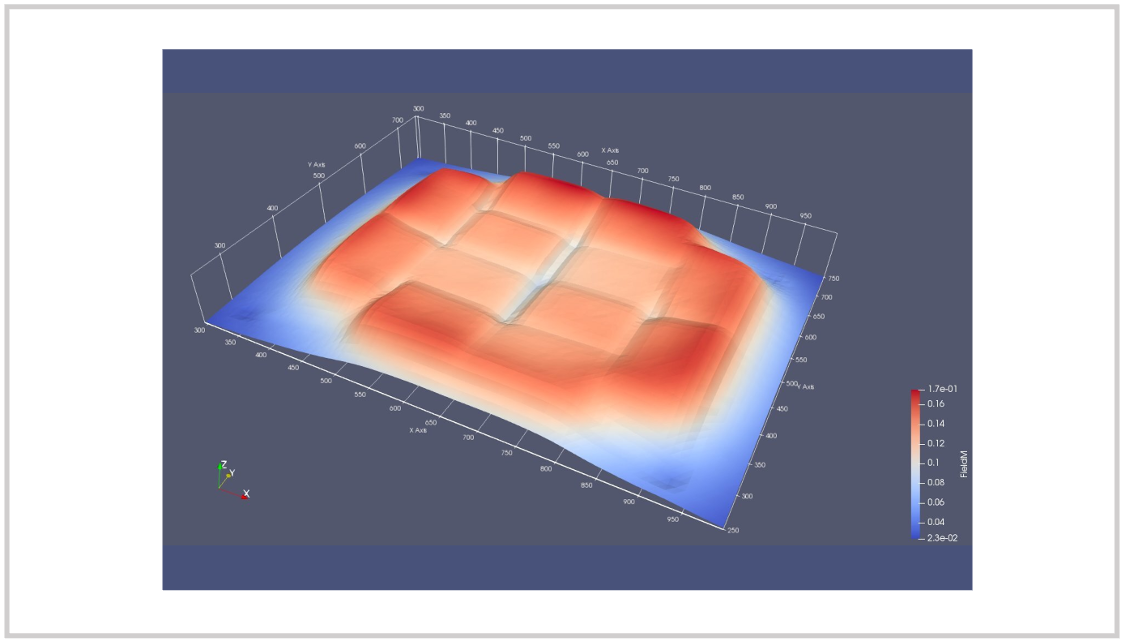

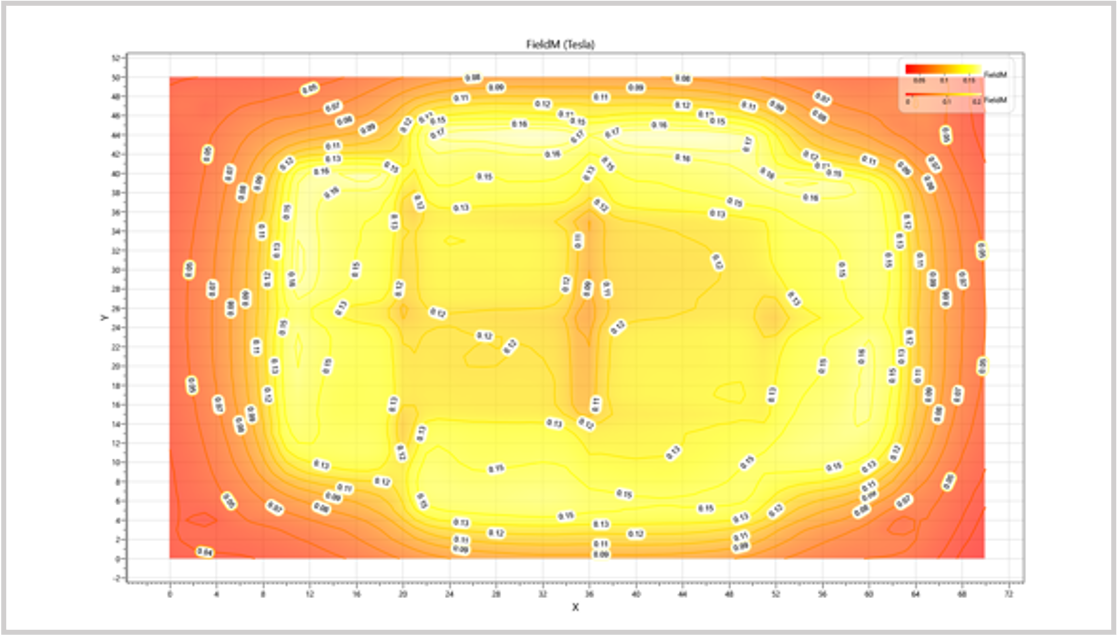

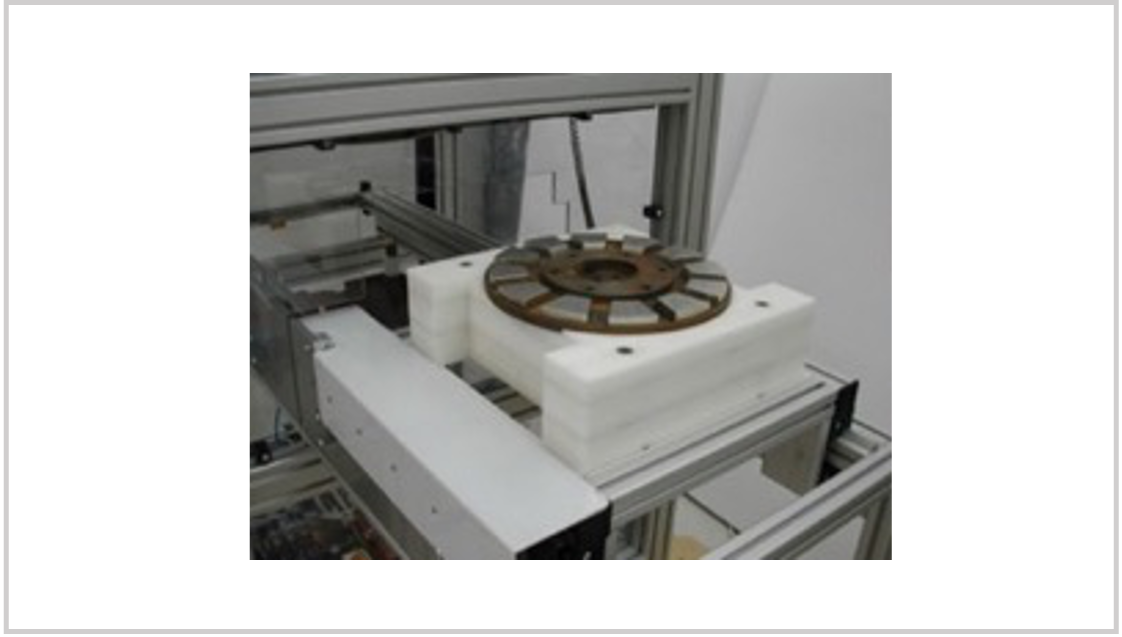

Find out more about Magnet Scanners

Magnetisers for all applications including aerospace and automotive applications

Hirst Magnetics has been producing magnetisers since the 1960’s and its bench-top magnetisers, magnetising fixtures, workstation magnetisers and volume production magnetising systems are trusted by the world’s leading companies in industries ranging from aerospace and electronics to medical equipment and automotive.

These magnetisers can be used with all permanent magnet materials including Ferrite, AlNiCo, NdFeB and SmCo.

Find out more about Hirst magnetisers

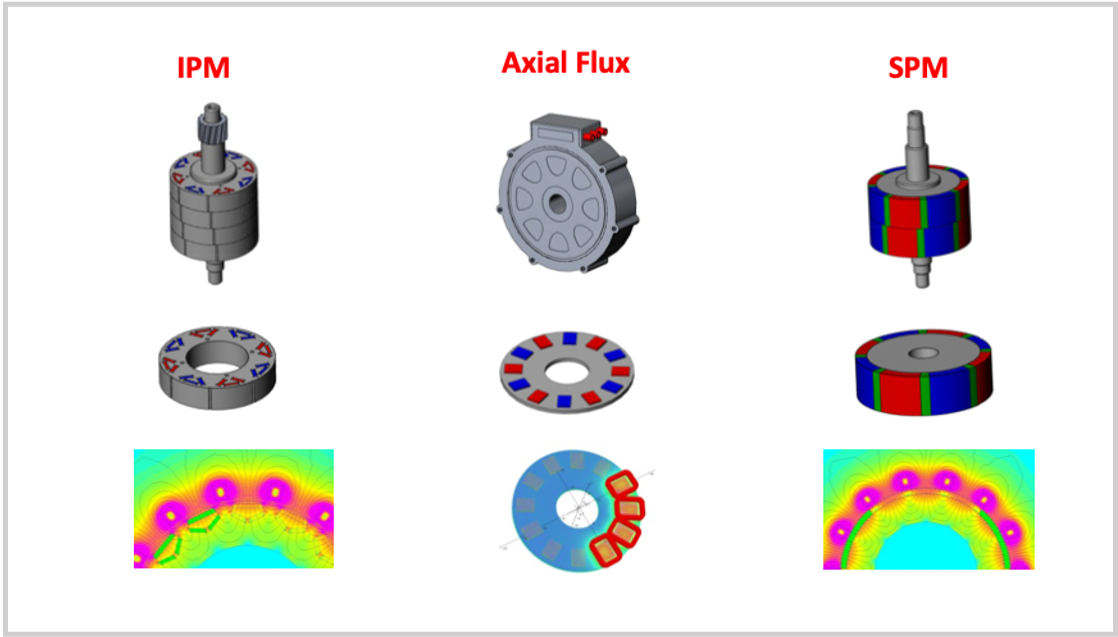

Applications

Permanent magnets are everywhere from aerospace to automotive they are in the vast majority of electric motors. They are used in a huge range of sensors to offshore wind generators and every loudspeaker and every microphone in every phone.

Hirst has been providing industry leading solutions for over 60 years.

Hirst is the leading provider of pulse field magnetometers (PFMs) used by magnet manufacturers to develop and characterise the high performing magnets underpinning these applications.

Demagnetisers

Hirst Magnetics has been producing demagnetisers since the 1960’s and its bench-top demagnetisers, workstation demagnetisers and volume production demagnetising systems are trusted by the world’s leading companies in industries ranging from aerospace and electronics to medical equipment and automotive.

A common problem in industry is residual magnetism in parts after machining or working. Often parts stick together, proving difficult for additional processing. Another typical problem after machining is that parts can pick up swarf, and even washing can prove ineffective. By demagnetising parts these problems can be alleviated.

Find out more about Hirst demagnetiser range.

Recent News

Intermag 2026

Hirst is sponsoring Intermag 26 and exhibiting there from 13-17th April 2026 in Manchester, UK…

Motors, Drive Systems & Magnetics 2026

Hirst are exhibiting and speaking at Motor, Drive Systems & Magnetics – 3-5th March 2026,…

The Magnetics Show Europe 2026

Hirst is exhibiting at The Magnetics Show – EU on the 24-26th February 2026 in…