The third revision of the PFM08 hardware platform contains improvements to the Automated Sample Handling (AH) Pulsed Field Magnetometers (PFM) specifically the PFM08-10 HT AH and the PFM08-40 HT/MT AH making these fully modular with interchangeable pickup coils, faster charging, class leading precision sample temperature control and extended sample temperature test ranges. The class leading precision sample control is further improved with theContinue reading “Generation 8 PFM – revision 3 hardware delivers fully modular PFMs”

Category Archives: Technology

New Automated sample Handling (AH) version of PFM08-10 added to the Generation 8 PFM range

The new 08-10 AH version brings the measurement automation technology of the 08-40 to the best selling but previously manual 10mm diameter sample PFM, the PFM08-10 MH. The 08-10 AH price is comparable to the PFM08-10 HT MH (which replaced the older PFM14 in 2023) but offering all the labour savings of the 08-40, makingContinue reading “New Automated sample Handling (AH) version of PFM08-10 added to the Generation 8 PFM range”

Hirst presents latest results at The Magnetics Show Europe

Dr Robin Cornelius, CTO at Hirst presents the latest results from the generation 8 PFM (Pulsed Field Magnetometer) at The Magnetics Show Europe, Amsterdam 3-4th Dec 2024 in a talk entitled “25 years of industrial PFMs” on the UK MagSoc stage at the conference. This joint presentation was a collaboration between Hirst Magnetic Instruments LtdContinue reading “Hirst presents latest results at The Magnetics Show Europe”

PFM08-40 range extended with addition of SC-05 kit to test samples down to 1x1x1mm

The small sample kit is capable of testing samples down to 1x1x1mm with a temperature range from 17 to 30℃ – via a kit containing both a high sensitivity 5mm Standard Coil (SC-05) and sample holders that can be fitted to the PFM08-40 HT or MT (by the user in about 30mins) allowing the PFM08-40Continue reading “PFM08-40 range extended with addition of SC-05 kit to test samples down to 1x1x1mm”

Generation 8 PFM range extension – revision 2 hardware

Hirst has added a high temperature small sample kit to its best selling PFM08-10 product range. The small sample kit is capable of testing samples as small as 1x1x1mm at temperatures up to 150℃ – this is via a SHS-05-HT stick that can be added to the small sample kit (SHS-05-kit). One of the mainContinue reading “Generation 8 PFM range extension – revision 2 hardware”

Hirst wins Most Innovative product of the show at The Magnetics Show, USA

Hirst Magnetic Instruments is proud to announce that at The Magnetics Show in Pasadena 22&23rd May 2024, that Hirst won Most innovative product of the show for the 8th Generation PFM range. Building on 25 years of commercial PFMs at Hirst, Dr Robin Cornelius was proud to accept the award on behalf of the team.

Hirst presents latest PFM results at The Magnetics Show USA

Dr Robin Cornelius, CTO at Hirst presents the latest results from the generation 8 PFM (Pulsed Field Magnetometer) at The Magnetics Show USA 22&23rd May 2024 in a talk entitled “Applications for Fast Repeatable Measurements”

MCSD-100J touch screen production magnetiser

Hirst are pleased to announce the release of the MCSD100J-T, a powerful precision microprocessor-controlled capacitor discharge Magnetiser, Charger, Setter, Demagnetiser. This is the new 4th generation of the ever popular industry workhorse MCSD100J. The MCSD series is widely used across industry for the setting and calibration of magnets and magnet assemblies. Particularly magnet materials such asContinue reading “MCSD-100J touch screen production magnetiser”

25 years of commercial PFMs at Hirst Magnetic Instruments

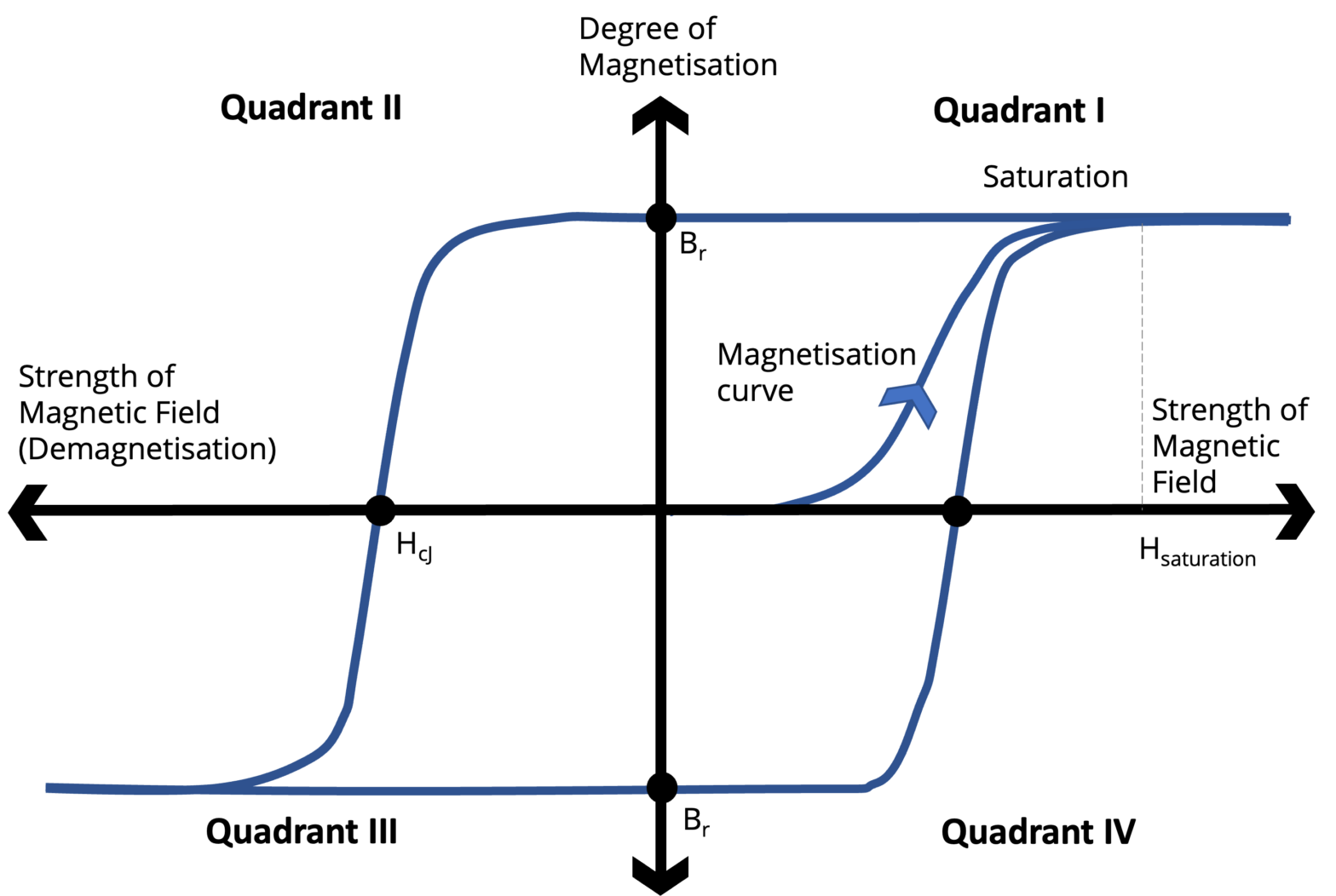

The first commercially available Pulsed Field Magnetometer (PFM) from Hirst was announced in 1998 (with the first machine shipped in 1999) but research work had been started 10 years earlier as it was clear modern high coercivity magnets could not always be measured on the traditional permeameters due to pole piece saturation and faster testsContinue reading “25 years of commercial PFMs at Hirst Magnetic Instruments”

Launch of GM09-1 Gaussmeter

Hirst Magnetic Instruments Ltd, is pleased to announce the launch of a new Gaussmeters the GM09-1. The GM09-1 features a touch-screen interface and rechargeable Li-ion battery compatible with the extensive range of Hirst Hall sensor probes. Built-in “App” modes ensure standard tests and measurements can be carried out with ease and minimal effort. The GM09-1 isContinue reading “Launch of GM09-1 Gaussmeter”