Hirst recently completed two orders for magnetising and calibration solutions, for two bespoke magnetic parts used in the aerospace industry.

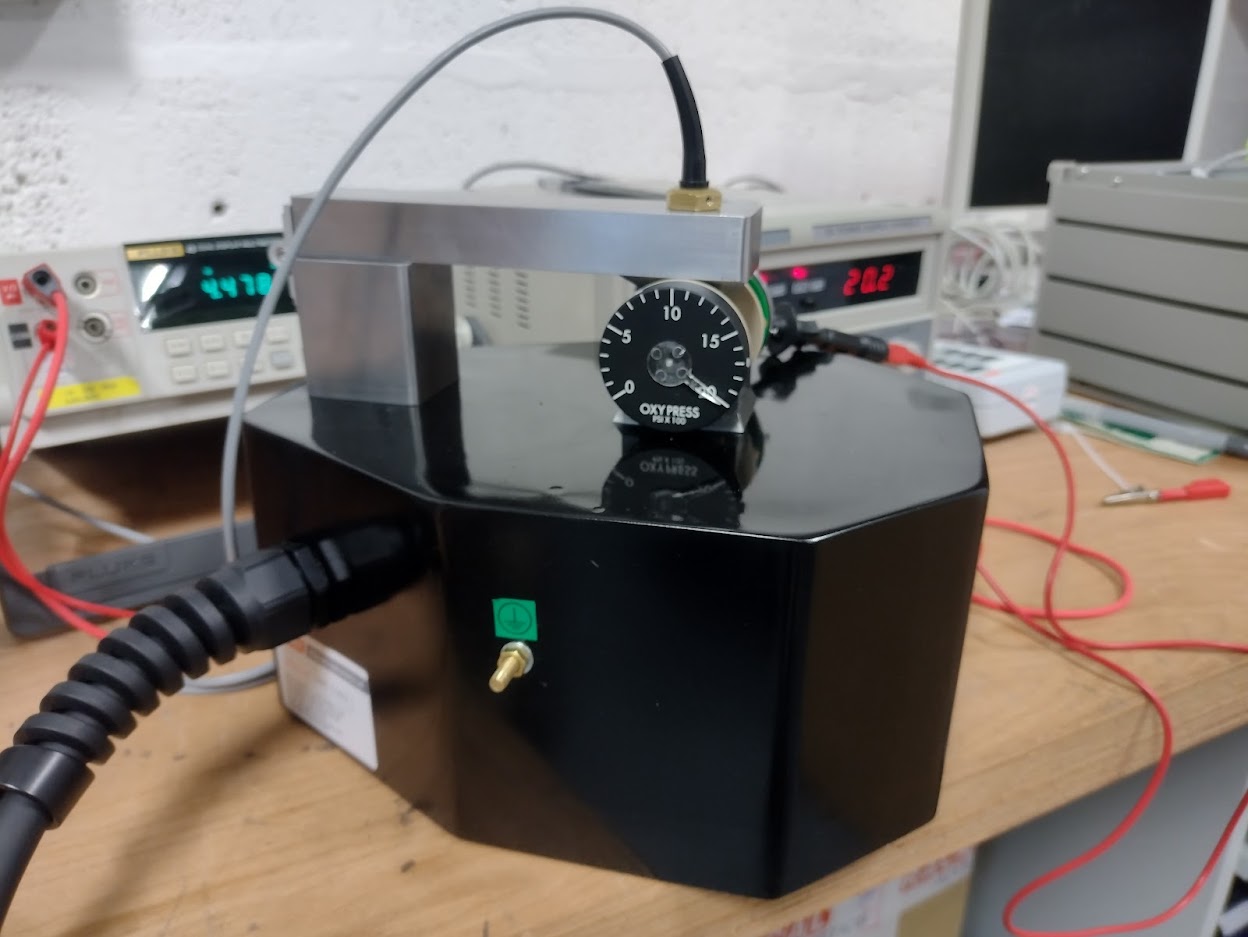

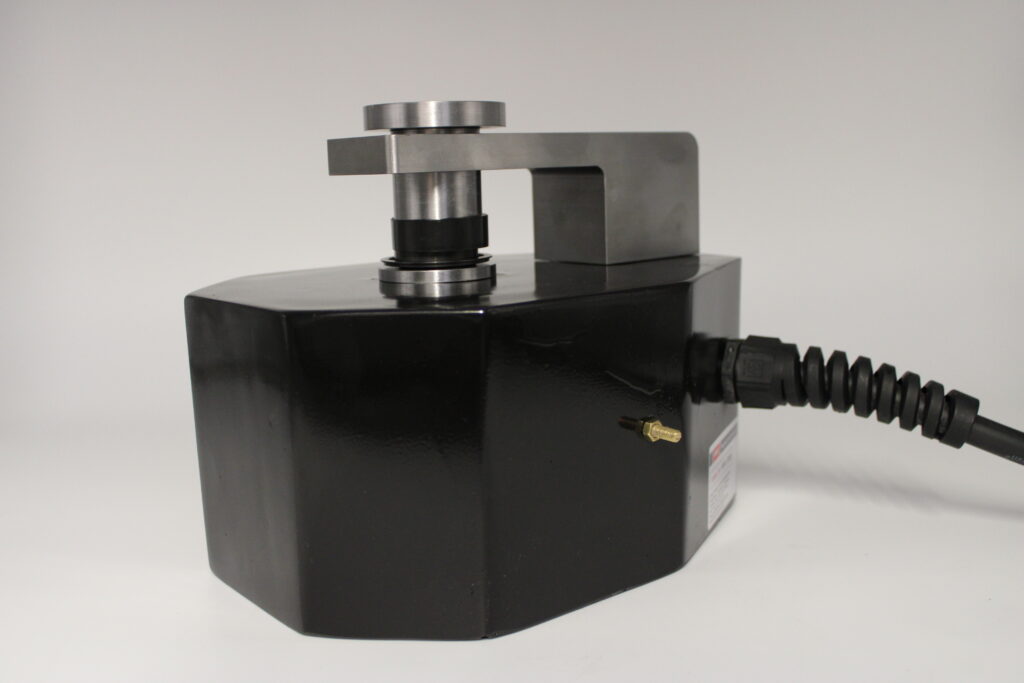

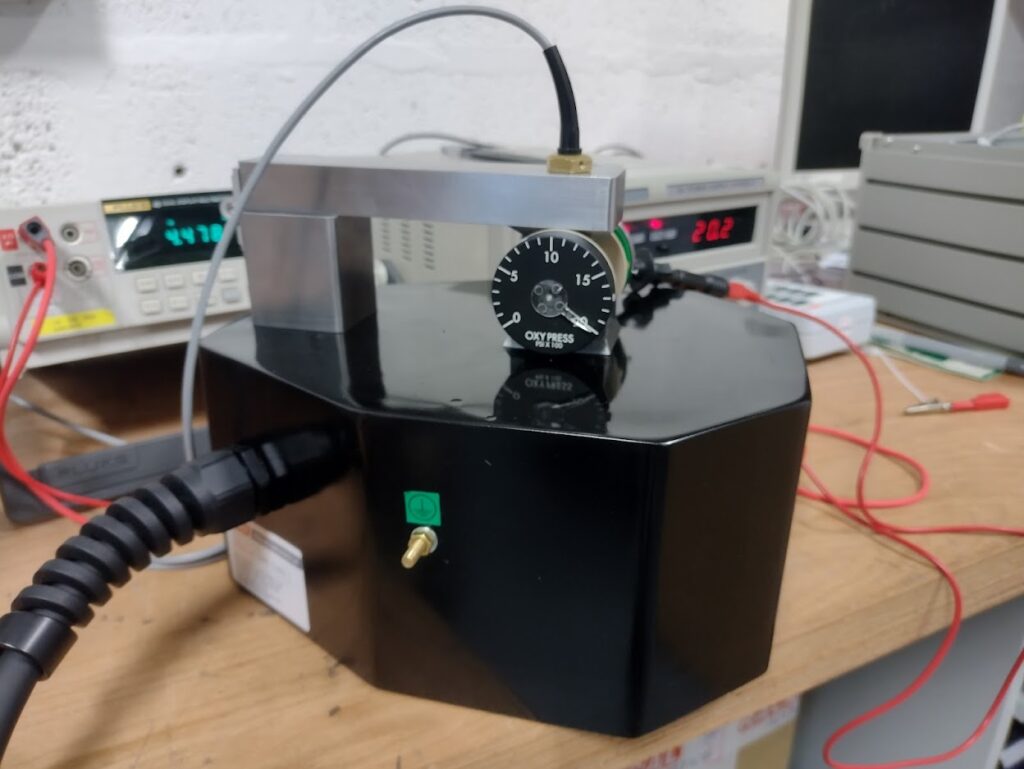

In both cases, we designed and built custom tooling compatible with a J2A fixture, to suit clients’ parts. The J2A is a widely used fixture for magnetising and demagnetising small assemblies. It is very adaptable, and over the years Hirst has made hundreds of these fixtures.

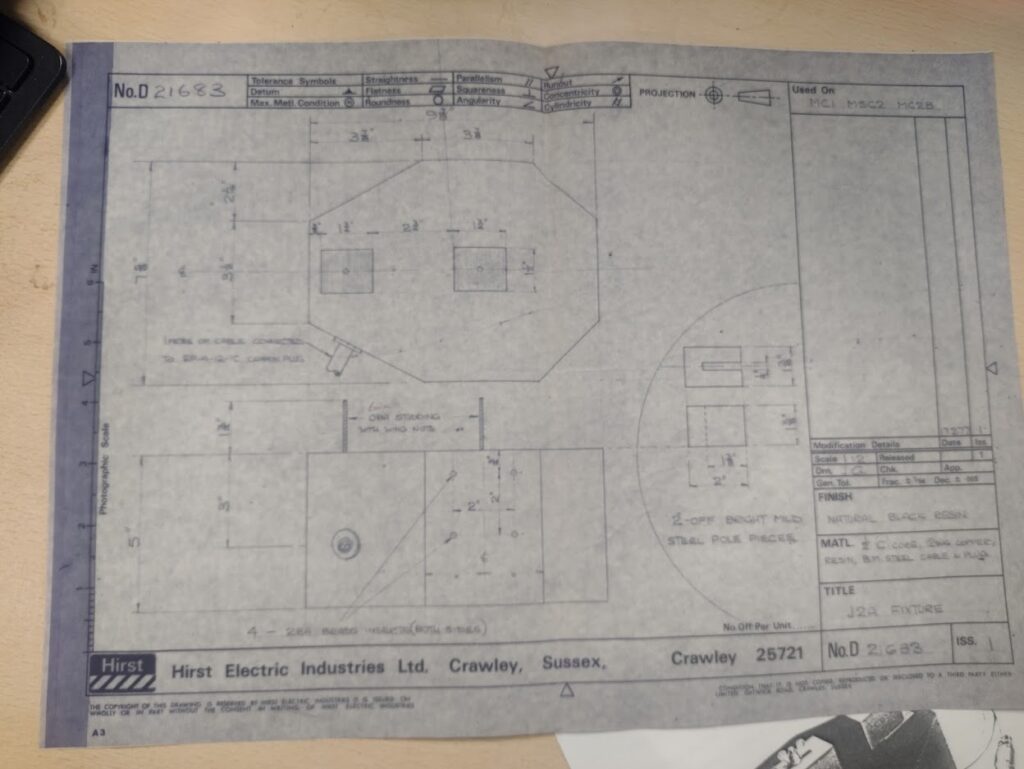

We still have the original hand drawn blueprints (and yes, they are actually blue), from 1965, when the fixture was first introduced. We even have customers out there still using some of these original fixtures frequently. We think 50+ years’ service represents fairly good value for money!

We have made a few minor changes over the years, and it is now all drawn up in our 3D CAD system, but the design has changed little in all this time.

Back in the 1960s we would have paired this with a MC2 magnetiser.

Time has moved on a little on the magnetiser side, and these days we supply the J2A more often than not with our MCSD100J, a desktop magnetisers which can be linked up to a gaussmeter and a PC for calibration and automated sequences.

If you have a part that requires magnetising, demagnetising, or calibrating, we can certainly come up with a way of doing this for you. We have the knowledge and experience, and love a challenge!