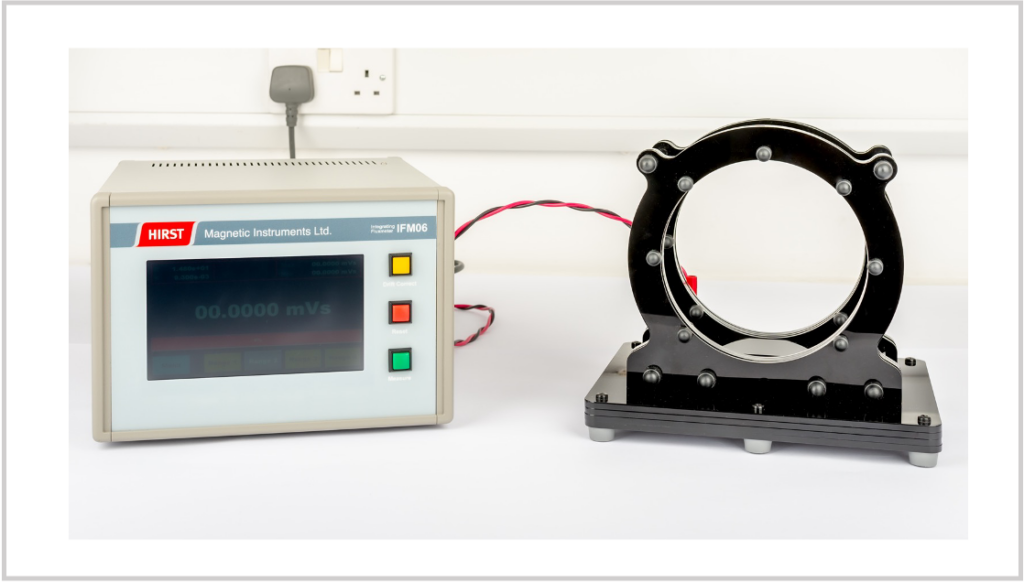

The IFM06 Fluxmeter measures the total magnetic flux in a volume contained within a coil (such as Helmholtz coils) whereas a gaussmeter measures the total flux density at a point where the probe is located. The IFM06 can measure magnetic flux, magnetic flux density or magnetic field strength.

The IFM06 digitally integrating flux meter is the most accurate and stable Hirst fluxmeter so far (supplied fully calibrated). This 6th generation of fluxmeter technology incorporates Hirst propriety Zero Drift Technology (ZDT) providing the most stable flux readings available in this the latest generation Hirst instrument.

Key benefits

- High stability and Automatic Drift Correction via proprietary Hirst Zero Drift Technology (ZDT).

- Accuracy and reproducibility of +/- 0.5% supplied calibrated and ready to use.

- Resolution – Get the best measurement resolution with 4 high sensitivity measurement ranges.

- Easy-to-use – 7inch touch screen display for fast set-up and robust buttons for taking simple measurements.

- Choice of Measurement units – The IFM06 can measure magnetic flux, magnetic flux linkage, magnetic flux density or magnetic field strength with direct readings in Volt-Seconds, Webers, Maxwells, Tesla*, kA/m*, Oersted* and Gauss* (* with a calibrated coil).

- Coils – Customisable with a wide variety of measuring coils (Helmholtz coil for measurement / quality control applications or a custom search coil or coil fixture for production magnetisation).

- User customisable graphical display options allow deeper understanding of the measured signal over time.

- Communications – A range of industry standard connectors USB, RS232, PLC Digital Interface, Analogue Outputs to access SCPI Instrument Control and CANopen interfaces to allow data logging and integration into production systems and control of Hirst magnetisers and de-magnetisers.

- Production control – Programmable with user modifiable measurement, magnetisation / de-magnetisation control programmes with pass/fail limits.

- High Security – Admin passcode lock for production applications.

Applications

- Designed for both factory floor and laboratory use across a range of applications including motors, loudspeakers, sensors, metrology and materials research.

- Laboratory based magnetic field measurement of soft and hard magnetic materials using Helmholtz coil pairs

- Quality control of permanent magnetic and assemblies such as magnetised sensor component, motor assemblies and loudspeaker using Helmholtz coils and precision jigs to increase measurement accuracy.

- High yield industrial magnetisation – the IFM06 Fluxmeter can provide the feedback in closed loop control of Hirst Magnetiser systems for optimal yield in production-line magnetisation of permanent magnet rotors, sensors, loudspeakers and many other applications.

When to use an IFM06 fluxmeter

Examples of when to use the IFM06 integrating fluxmeter include:-

To determine total flux of a magnet using Helmholtz coils

With a pair of Helmholtz coils connected to the IFM06 Integrating Fluxmeter the sample to be tested is placed within the coils. Using this set up the IFM06 Integrating Fluxmeter can be used to determine the total magnetisation of the sample.

To check and control a magnetisation process

The IFM06 Fluxmeter can provide the feedback in closed loop control of Hirst Magnetiser systems for optimal yield in production line magnetisation of permanent magnet rotors, sensors, loudspeakers and many other applications. A search coil is embedded into a magnetising fixture (which holds the material / part to be magnetised). The magnet charger magnetises the sample the IFM06 Integrating Fluxmeter measures the sample’s total magnetisation and determines if the magnetisation has achieved the desired result and can display pass / fail. In addition, the IFM06 is able control the magnetiser to incrementally magnetise the part to ensure optimal yield in the process.

A custom sensing coil can be added to the Hirst IFM06 integrating fluxmeter this allows for a fast, accurate and a low-cost measuring technique to monitor the quality of permanent magnet assemblies prior to final assembly into the motor.

Sample batch testing can be used to verify specifications of the magnet assemblies prior to assembly.