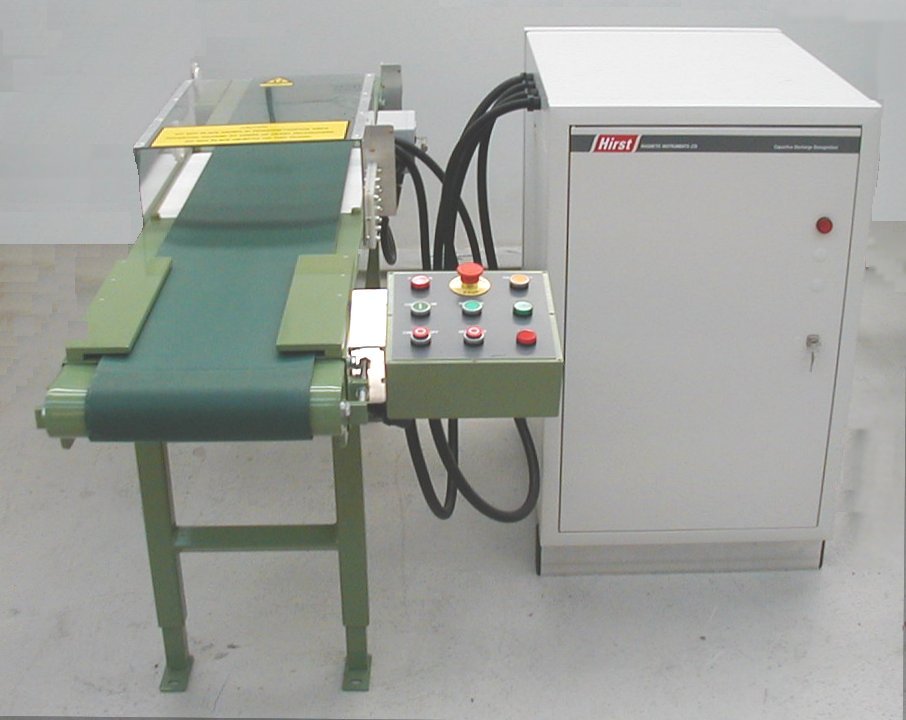

Hirst offer semi-automated and fully automated production systems covering all aspects of integration either with you directly or with your production automation partner. A fully automated approach ensures maximum throughput, easy compliance with health and safety standards around magnetic fields and the highest process yield.

The processes involved in magnetisation are as follows :

- Insert the assembly into the magnetiser fixture – ensuring precise alignment of the part, sometimes clamps are employed to ensure optimal part location during the magnetising step handling. Conveyers, hoppers and robotic options can be used depending on the application

- Magnetise the assembly – using a single or multi-shot process or a step-and-repeat for more complex assemblies such as axial flux rotors

- Verify the magnetisation process – using Gaussmeter probes attached to the magnetising fixture or Fluxmeters coupled to the primary coil or secondary sensing coils.

- Remove the part – extract the part from the fixture and move it the the next part of the process

If your project required production-line integration, please contact us.

All Hirst magnetisers are ideally suited for integration into automated cells due to the wide range of industry standard communication and control interfaces such as SCPI, PLC and CANopen.